Mastertint® White Masterbatches

Mastertint® White masterbatches contain high quality titanium dioxide. The type of titanium dioxide used in each product is selected to match the requirements of the intended application.

Certain products also contain micronized calcium carbonate of exceptional whiteness, chemical purity and particularly low abrasivity, which acts as an anti blocking agent for film, contributes to increased opacity, reduces cooling time, increases rigidity and reduces use cost.

Functional additives such as antistatics and processing aids are incorporated in certain products for dual effect.

For the production of our Mastertint® White masterbatches we cooperate with the major suppliers of titanium dioxide and we accept only lots meeting the technical specifications

Our Mastertint® White masterbatches are processed in state of the art compounding lines and each lot is subjected to a series of tests, which are based on international standards.

We have set strict tolerance limits for each parameter, having studied the requirements for each end use. Parameters controlled are pigment content, color, dispersion quality, moisture content and pellet size and quality.

More specifically Mastertint® White masterbatches offer the following advantages:

Composition and Color Consistency

Consistency of composition is ensured by gravimetric dosing feeders with a maximum deviation tolerance of ± 0.5%.

Titanium dioxide and calcium carbonate content are controlled in the lab by ashing (ISO 3451/1), i.e. a known quantity of masterbatch is subjected to pyrolysis and the percentage content of each ingredient is calculated on the basis of residue weight after heating at a specific temperature.

Whiteness (color) is controlled by the use of a color computing spectrophotometer.

Excellent Pigment Dispersion Quality

Dispersion quality is probably the most important parameter of a masterbatch, as it determines the color strength obtained from the pigments. Also, better dispersion quality minimizes the down time of the users’ production equipment for filter cleaning or replacement.

Quality of pigment dispersion is assured by the excellent compounding capability of our extruders and the continuous melt filtration that retains any oversized particles and foreign matter.

Dispersion quality is controlled at the lab either by optical evaluation of blown film or by the filter pressure value test (EN 13900-5), depending on the application.

Low Moisture Content

The presence of volatiles, in most cases moisture, can create production problems and / or can affect the quality of the final product.

A very low volatile content is assured by the drying equipment in which pellets are processed before they are conveyed to the storage and bagging units. Moisture content is laboratory controlled by Moisture Analyzers.

Excellent Pellet Quality

Pellet size and uniformity is important for feeding the masterbatch by volumetric dosing equipment and for the uniform coloration of the final product.

Excellent pellet quality is assured by the state of the art pelletizing and pellet classifying systems of our compounding lines. Fines, longs and oversized pellets are separated, so that only conforming pellets reach the storage and bagging units.

Pellet quality is controlled by pellet counting of one gram of masterbatch and by visual checks of the pellets to detect any irregularities.

Consistent Quantity of Masterbatch per Bag

Consistent quantity of masterbatch packed in each bag is assured by our automated bagging and weighing equipment.

Product Range and Applications

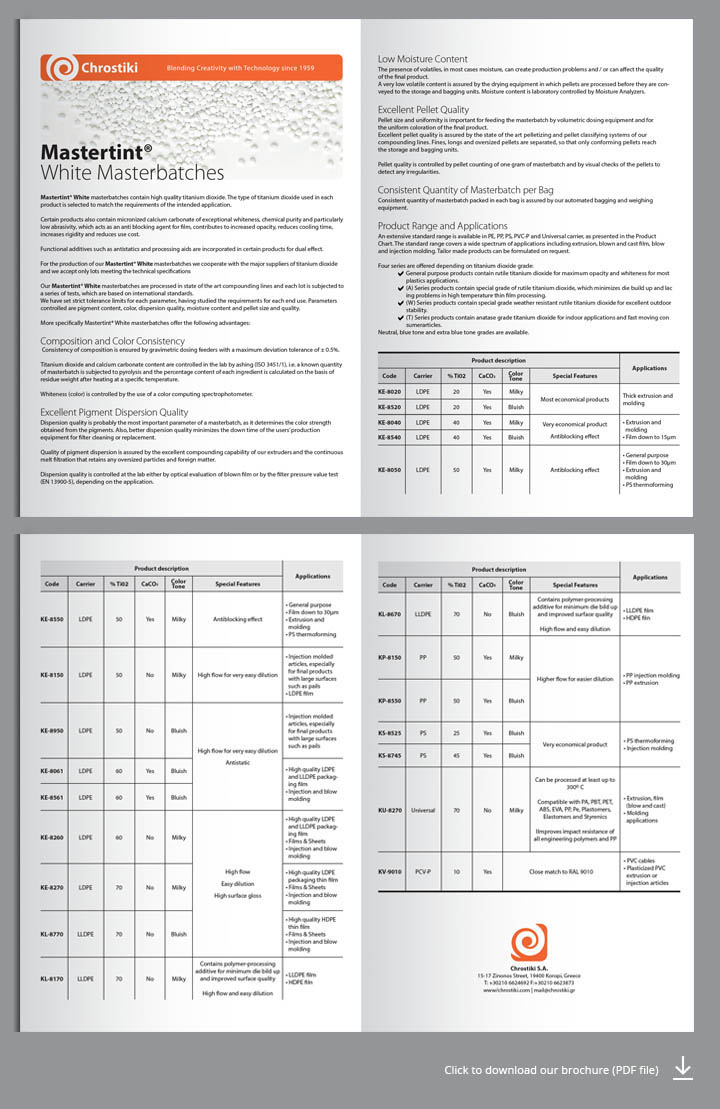

An extensive standard range is available in PE, PP, PS, PVC-P and Universal carrier, as presented in the Product Chart. The standard range covers a wide spectrum of applications including extrusion, blown and cast film, blow and injection molding. Tailor made products can be formulated on request.

Four series are offered depending on titanium dioxide grade:

- General purpose products contain rutile titanium dioxide for maximum opacity and whiteness for most plastics applications.

- (A) Series products contain special grade of rutile titanium dioxide, which minimizes die build up and lacing problems in high temperature thin film processing.

- (W) Series products contain special grade weather resistant rutile titanium dioxide for excellent outdoor stability.

- (T) Series products contain anatase grade titanium dioxide for indoor applications and fast moving consumer articles.

Neutral, blue tone and extra blue tone grades are available.